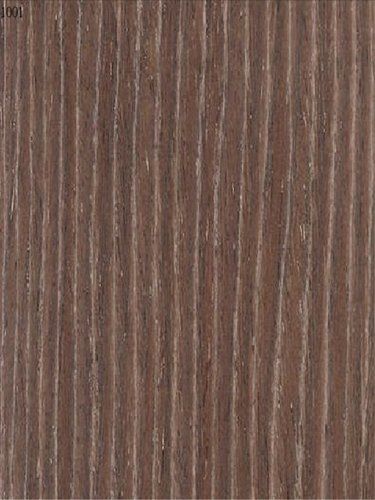

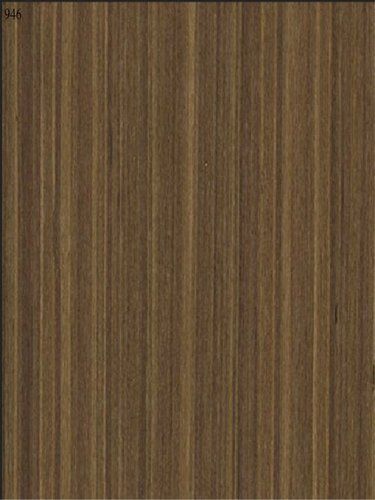

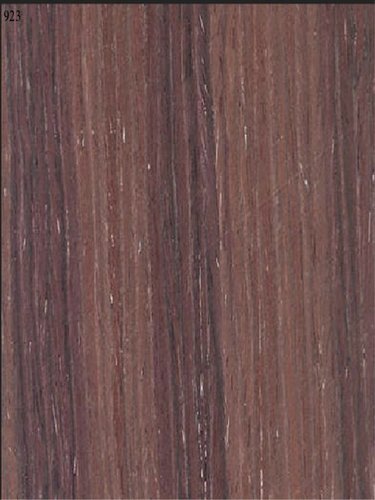

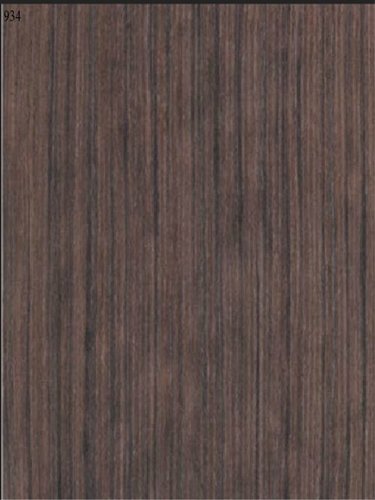

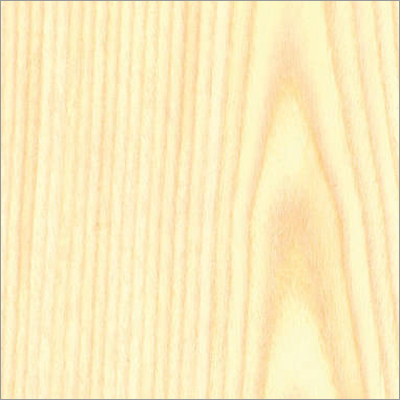

Engineered Recon Veneers

Engineered Recon Veneers Specification

- Glue

- Melamine or Urea Formaldehyde

- Core Material

- Poplar, Eucalyptus, or Mixed Hardwood Core

- Surface Treatment

- Calibrated and Sanded

- Thickness

- 0.5 mm to 2 mm

- Density

- 750 Gram per cubic centimeter(g/cm3)

- Formaldehyde Emission Standards

- E1 Standard (Low Emission)

- Tolerance

- 0.1 mm

- Moisture Content

- 6% 12%

- Product Type

- Engineered Recon Veneer

- Timber Type

- Reconstituted Wood

- Usage

- Interior Decoration, Furniture, Paneling, Door and Cabinet Surfacing

- Grade

- A Grade / Premium

- Size

- 8 x 4 Feet (Standard)

- Shape

- Rectangular

About Engineered Recon Veneers

As a leading firm, we are successfully engaged in offering to our respected customers brad array of Engineered Recon Veneers. Our professionals always keep an eye on the processing phase of veneers to maintain consistency in operations. These veneers are chemically treated by employing advanced and latest technologies. Acknowledged due to their smooth finish, longevity and optimum strength, these are preferred across the market. Moreover, we charge nominal prices for our exclusive stock of Engineered Recon Veneers.

Features:

- Fine polishing

- Silky surface

- Exciting shades

Superior Quality and Sustainability

Our engineered recon veneers are produced from responsibly sourced reconstituted wood, ensuring both eco-friendliness and high durability. Designed with advanced calibration and sanding techniques, the veneers offer a smooth, consistent surface suitable for sophisticated interiors. Meeting E1 formaldehyde emissions standards, these veneers are safe for indoor applications and guarantee long-term satisfaction.

Versatile Applications in Modern Design

These veneers are perfect for a wide range of interior uses, including wall paneling, furniture surfaces, decorative doors, and stylish cabinet finishes. Their standard 8 x 4 feet size and dense, rectangular build make installation straightforward, providing designers and manufacturers with a reliable material that adapts to varied creativity and functionality needs in contemporary spaces.

FAQs of Engineered Recon Veneers:

Q: How are engineered recon veneers manufactured?

A: Engineered recon veneers are produced using reconstituted wood, which involves layering and bonding wood fibers or sheets with melamine or urea formaldehyde glue. The materials are then pressed, calibrated, and sanded for a precise thickness between 0.5 mm to 2 mm, resulting in uniform, high-quality veneers.Q: What makes engineered recon veneers suitable for furniture and interior decoration?

A: These veneers combine strength, flexibility, and a premium finish, making them ideal for furniture, interior paneling, doors, and cabinets. The A-grade or premium grading, calibrated surface, and low formaldehyde emission meet stringent quality and safety standards required for indoor furnishings.Q: Where can I use these veneers in my project?

A: You can use engineered recon veneers in residential and commercial interiors for wall paneling, custom furniture, cabinetry, doors, and other decorative surfaces. Their standard size and rectangular shape ensure they are compatible with most woodworking and interior design requirements.Q: What is the benefit of the E1 formaldehyde emission standard?

A: The E1 standard signifies low formaldehyde emissions, ensuring your indoor air remains healthy and safe. This level of emission is especially beneficial for homes, offices, and places where occupants well-being is a priority, minimizing health risks associated with higher formaldehyde levels.Q: How do I install and care for engineered recon veneers?

A: Installation involves precise cutting to your required size, followed by lamination onto the substrate using appropriate adhesives. Care involves periodic cleaning with a soft cloth and avoiding exposure to excessive moisture to maintain their smooth, sanded finish.Q: What types of core material are available in these veneers?

A: The core materials offered include poplar, eucalyptus, or a mix of hardwoods, all of which contribute to the veneers strength, density, and versatility. These options enable customized solutions depending on your specific design and structural needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

Silver Wenge Veneers

Feature : Placeholder

Product Type : Silver Wenge Veneers, Other

Size : Placeholder

Grade : Placeholder

Finish Type : Placeholder

Usage : Placeholder

Trendy Teak Veneers

Feature : High durability, Attractive appearance, Smooth texture

Product Type : Other, Teak Veneer

Size : 8 x 4 Feet

Grade : A Grade

Finish Type : Matte/Semi Gloss

Usage : Interior decoration, Furniture, Paneling

Rose Nut Quarter Veneers

Feature : Natural Grain Appearance

Product Type : Veneer, Other

Size : 8ft x 4ft

Grade : Premium

Finish Type : Matte

Usage : Furniture Interior Applications

Brazilian Rosewood Veneers

Feature : High durability, rich color, elegant grain

Product Type : Other, Natural Wood Veneer Sheet

Size : 8 ft x 4 ft, customized sizes available

Grade : A Grade

Finish Type : Natural, Smooth

Usage : Furniture, interior decoration, musical instruments

Send Inquiry

Send Inquiry