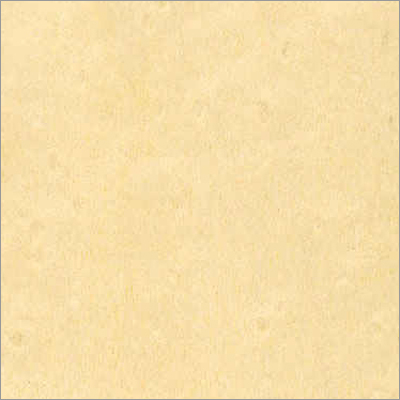

Bem Cream Veneer

Bem Cream Veneer Specification

- Tolerance

- 0.2 mm thickness tolerance

- Formaldehyde Emission Standards

- E1 grade, compliant with EU standards

- Core Material

- Veneer only (typically bonded to plywood or MDF)

- Moisture Content

- 8% to 12%

- Timber Type

- Creamwood / Bemwood

- Usage

- Interior decoration, furniture manufacturing, cabinetry, wall paneling

- Grade

- Premium grade (A grade)

- Size

- 8 ft x 4 ft (2440 mm x 1220 mm)

- Feature

- High durability, elegant appearance, uniform texture, easy to install

- Shape

- Sheet

About Bem Cream Veneer

Ever since our successful inception, we are engaged in the industry as leading manufacturer and supplier of Bem Cream Veneer. Our professionals are specialized in making the logs weather resistant and tough by precise processing techniques. For processing these veneers, entire raw wood is procured from the reliable vendors of the market. Further, we make available the range of Bem Cream Veneer at highly discounted prices.

Features:

- Sturdy and light in weight

- Precise polishing

- Resistant to water and termite

Superior Durability and Timeless Beauty

Crafted for longevity and sophistication, Bem Cream Veneer offers exceptional durability and a consistent, elegant look. Its surface is designed to withstand daily wear while maintaining a refined appearance. The uniform texture ensures an appealing finish, making it suitable for high-end furniture, cabinetry, or wall panels. This product provides a modern yet natural touch to any interior setting.

Precision Manufacturing and Compliance

Manufactured to meet stringent quality standards, every Bem Cream Veneer sheet maintains a thickness tolerance of 0.2 mm and an ideal moisture content of 8% to 12%. It is strictly E1 grade for formaldehyde emissions, aligning with EU standardized safety protocols. These qualities guarantee not just reliability and easy installation, but also peace of mind for both residential and commercial use.

Versatility in Application

Bem Cream Veneer is highly adaptable, fitting seamlessly into interior decoration, furniture production, cabinetry work, and wall paneling projects. The sheet format (8 ft x 4 ft) allows for creative flexibility. Whether used by manufacturers, exporters, or suppliers, its compatibility with plywood or MDF as a core enhances substrate options, ensuring an elegant, enduring finish for multiple design contexts.

FAQs of Bem Cream Veneer:

Q: How is Bem Cream Veneer typically used in interior design projects?

A: Bem Cream Veneer is commonly used to enhance furniture, cabinetry, wall panels, and other interior surfaces. It is usually bonded to substrates like plywood or MDF to create an elegant, uniform surface finish that complements both contemporary and classic interior styles.Q: What are the key benefits of choosing Bem Cream Veneer for furniture manufacturing?

A: Choosing Bem Cream Veneer ensures high durability, a sophisticated appearance, and ease of installation. Its uniform texture and precision manufacturing result in consistent quality, while its compliance with E1 grade formaldehyde emissions makes it a safer option for interior applications.Q: Where can I install Bem Cream Veneer for optimal results?

A: Bem Cream Veneer performs exceptionally well on indoor applications such as wall paneling, cabinet doors, furniture surfaces, and decorative elements in homes, offices, hotels, and retail environments. Its elegant look enhances a wide array of interior spaces.Q: What core materials are compatible with Bem Cream Veneer?

A: This veneer is designed to be bonded to substrates like plywood or MDF, providing stability and strength while allowing the veneer to showcase its attractive surface texture. These core materials are widely used in cabinetry, furniture, and wall paneling projects.Q: How does the manufacturing process address quality tolerance and moisture content?

A: Bem Cream Veneer is manufactured to maintain a precise thickness tolerance of 0.2 mm and a moisture content of 8% to 12%. This ensures the sheets are dimensionally stable, minimize the risk of warping, and are ready for immediate application in various woodworking projects.Q: What distinguishes Bem Cream Veneer in terms of environmental compliance?

A: The veneer adheres to E1 grade formaldehyde emission standards, aligning with EU environmental and safety guidelines. This makes it a responsible choice for spaces where indoor air quality and user safety are priorities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Natural Veneers Category

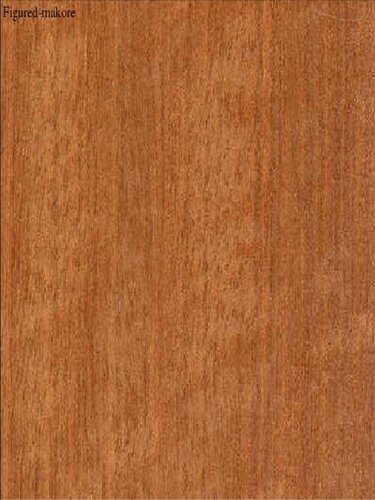

Figured-Makore Veneers

Grade : A

Product Type : Other, Wood Veneers

Finish Type : Natural

Wood Type : Hardwood

Size : Standard sizes available

Usage : Furniture paneling decoration

Sycamore Veneers

Grade : Premium

Product Type : Wood Veneer, Other

Finish Type : Natural

Wood Type : Sycamore

Size : Standard sizes available

Usage : Furniture wall paneling and decorative applications

Veneers 5

Grade : A+

Product Type : Veneers

Finish Type : Matte

Wood Type : Veneer Boards

Size : As required

Usage : Interior Decoration/ Furniture

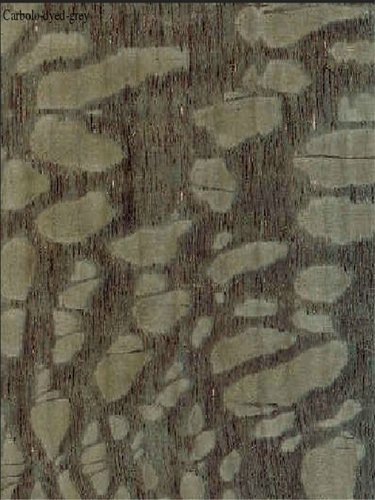

Carbolo-Dyed-Gray Veneers

Grade : A+

Product Type : Veneers

Finish Type : Matte

Wood Type : Veneer Boards

Size : As required

Usage : Interior Decoration/ Furniture

Send Inquiry

Send Inquiry