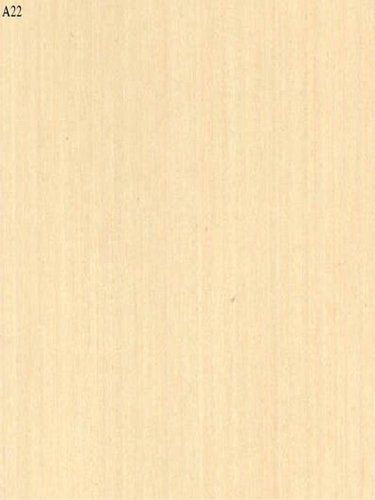

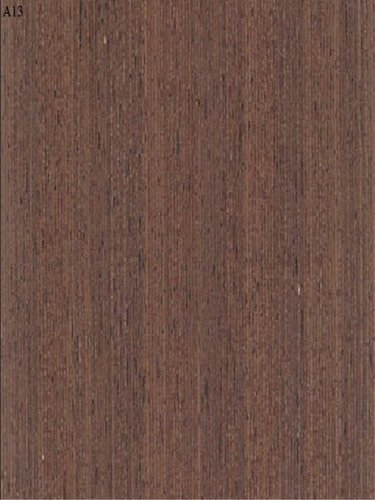

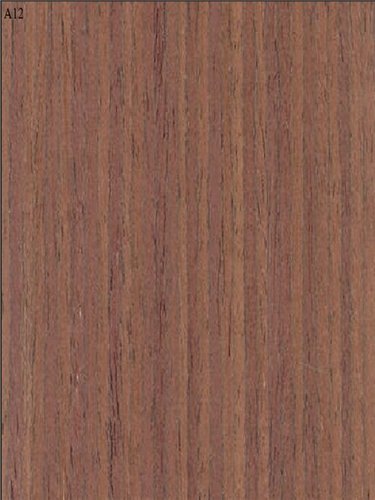

Durable Recon Veneers

Durable Recon Veneers Specification

- Formaldehyde Emission Standards

- E0/E1 Compliant

- Tolerance

- 0.05mm

- Core Material

- Poplar/Hardwood

- Moisture Content

- Below 8%

- Wood Type

- Reconstituted Wood

- Thickness

- 0.4mm to 2mm

- Load Capacity

- Standard for wall and furniture applications

- Product Type

- Recon Veneer Sheet

- Timber Type

- Engineered Wood

- Usage

- Interior Decoration, Furniture Manufacturing, Wall Paneling

- Grade

- A

- Size

- 8ft x 4ft

- Shape

- Rectangular

About Durable Recon Veneers

Made by utilizing sophisticated techniques and advanced tools, we manufacture and supply a broad collection of Durable Recon Veneers. Available in different shades, patterns, thickness and sizes, our complete gamut is most preferred by furniture industry. When applied for making different furniture, these veneers add charm to the entire finished gamut. Our quality approved spectrum of Durable Recon Veneers is safely stored and delivered to the clients end in a flawless manner.

Features:

- Wear & tear resistant

- High density

- Durable finish

- Anjlim

- Block Board

- Ash Dyed Green

- Ash Dyed Grey

- Bem Cream

- Brazialian-Oak

- Carbold-Dyed-Cream

- Carbold-Dyed-Gold

- Carolina Pine

- Plywoods

Engineered for Versatility and Style

Our Durable Recon Veneers deliver a seamless finish suitable for modern interiors. Engineered wood combines resilience with visual appeal, making it the material of choice for designers and manufacturers. Adaptable in a wide range of design applications, these veneers add sophistication to walls and furniture alike.

Precision Manufacturing Upholds Quality

Each veneer panel is produced using advanced manufacturing techniques, ensuring strict adherence to size tolerance and core material quality. The engineered wood is meticulously pressed and checked for uniformity in thickness, providing ease of handling and installation across diverse projects.

Sustainable and Safe Interior Solutions

With low formaldehyde emissions (compliant to E0/E1 standards), our recon veneers support a healthier indoor environment. Engineered for longevity, these panels resist warping and retain their look, making them a sustainable choice for residential and commercial environments.

FAQs of Durable Recon Veneers:

Q: How can Durable Recon Veneers be used in interior decoration?

A: Durable Recon Veneers are ideal for wall paneling, feature accents, and cabinetry, lending a refined finish to both contemporary homes and office spaces. Their excellent dimensional stability and elegant appearance make them suitable for creative design solutions.Q: What are the benefits of using engineered wood veneers compared to solid wood?

A: Engineered wood veneers like Durable Recon Veneers offer superior stability, consistent thickness, and reduced risk of warping compared to solid wood. They also promote efficient resource usage and are often more sustainable, without compromising on aesthetic appeal.Q: When should I choose veneer thicknesses between 0.4mm and 2mm?

A: Thinner veneers (0.4mm) are suited for detailed or curved applications, while thicker options (up to 2mm) provide greater durability and are preferred for high-traffic wall panels or robust furniture surfaces.Q: Where are Durable Recon Veneers manufactured and supplied from?

A: These veneers are manufactured, exported, imported, and supplied throughout India. As a trusted supplier, we ensure availability for bulk orders and consistent quality across all shipments.Q: What is the process for manufacturing recon veneers from engineered wood?

A: Recon veneers are crafted by slicing reconstituted wood, then bonding and pressing it onto a core material such as poplar or hardwood. This process guarantees uniformity in grain and color while meeting strict tolerances for thickness and moisture.Q: How does the E0/E1 formaldehyde emission compliance benefit users?

A: Compliance with E0/E1 standards means that Durable Recon Veneers have very low formaldehyde emissions, ensuring safer air quality indoors and promoting a healthier environment for occupants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

Canadian Cedar Veneers

Size : 8 x 4 Feet

Feature : Durable, Weather Resistant, Eco Friendly

Finish Type : Smooth

Grade : AA/AB

Product Type : Veneers

Wood Type : Natural Canadian Cedar

Wenge Veneers

Size : 8 x 4 ft

Feature : Smooth Texture

Finish Type : Matte

Grade : Premium

Product Type : Other, Veneer

Wood Type : Engineered Wood

Rose Crown Veneers

Size : 8ft x 4ft

Feature : Natural wood veneer finish

Finish Type : Matte

Grade : Premium

Product Type : Other, Veneer sheet

Wood Type : Rosewood

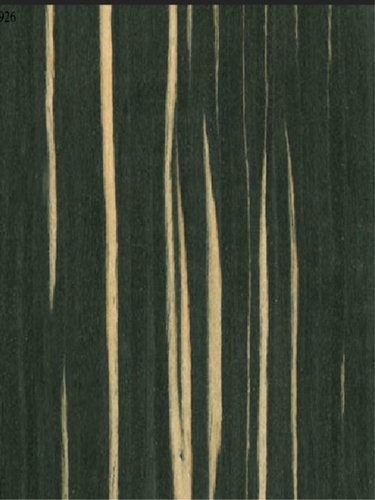

Titan Black Veneers

Size : Standard or customizable

Feature : Decorative design with black and natural streaks

Finish Type : Matte

Grade : Premium

Product Type : Veneer Sheet, Other

Wood Type : Natural Wood

Send Inquiry

Send Inquiry