Recon Natural Veneers

Recon Natural Veneers Specification

- Finish Type

- Matte / Glossy

- Tolerance

- 0.2 mm

- Formaldehyde Emission Standards

- E1 / E0

- Moisture Content

- 8% to 12%

- Wood Type

- Engineered / Recon Wood

- Thickness

- 0.4 mm to 0.6 mm

- Glue

- Phenol Formaldehyde / Urea Formaldehyde

- Load Capacity

- Suitable for low to moderate load applications

- Surface Treatment

- Smooth sanded / Finished

- Core Material

- Poplar, Gurjan or Hardwood core

- Timber Type

- Recon (Reconstituted) Wood

- Usage

- Furniture making, Interior decoration, Wall paneling, Doors

- Grade

- AA / Premium

- Size

- 8 ft x 4 ft

- Shape

- Rectangular

About Recon Natural Veneers

With an impressive growth record in the industry, we are actively engaged in manufacturing and exporting a durable gamut of Recon Natural Veneers. The offered veneers are widely used for designing different types of wooden items. Due to our advanced cutting and shaping machines, the entire range of Recon Natural Veneers is conveniently finished in flawless manner. Further, these veneers specifically complement furniture when applied with elegance.

Features:

- Weather resistant

- High strength

- Free from defects

Versatile Solutions for Modern Interiors

Recon Natural Veneers are tailored for contemporary interior design, offering elegant solutions for a variety of applications. They provide designers and manufacturers with the flexibility needed to achieve both functional and aesthetic goals. Whether for wall paneling or customized furniture, these veneers strike the perfect balance between appearance and performance. Their impressive durability, smooth finish, and eco-friendly standards make them a valuable asset in both residential and commercial projects.

Quality and Sustainability Combined

Engineered using high-grade poplar, gurjan, or hardwood cores, Recon Natural Veneers are manufactured to stringent quality standards. With low formaldehyde emissions certified to E1/E0 standards and a carefully controlled moisture content, these veneers support a healthier indoor environment. By opting for reconstituted wood, you contribute to sustainable forestry practices while enjoying consistent quality in every panel.

FAQs of Recon Natural Veneers:

Q: How are Recon Natural Veneers used in furniture making and interior decor?

A: Recon Natural Veneers can be laminated onto surfaces such as plywood, MDF, or particleboard to provide an attractive and durable finish for furniture, wall panels, and doors. They are ideal for enhancing visual appeal while maintaining structural integrity, thanks to their engineered construction.Q: What is the manufacturing process for Recon Natural Veneers?

A: Recon Natural Veneers are created by slicing reconstituted wood, which involves bonding thin layers of wood fibers with phenol or urea formaldehyde adhesives. These layers are then formed into sheets, pressed, and finished to achieve a smooth, consistent surface in matte or glossy options.Q: When should I opt for Recon Natural Veneers over traditional wood veneers?

A: Choose Recon Natural Veneers when you require uniform appearance, stable dimensions, and eco-friendly materials for your project. Their controlled manufacturing process ensures consistent grain and color, making them ideal where traditional veneers may show variability or limited availability.Q: Where can Recon Natural Veneers be applied within a building?

A: These veneers are suitable for a wide range of interior applications including wall paneling, cabinetry, doors, wardrobes, and decorative furniture elements. Their low to moderate load capacity makes them perfect for internal surfaces rather than structural or external use.Q: What are the primary benefits of using Recon Natural Veneers?

A: Key benefits include a consistent and customizable appearance, compliance with strict formaldehyde emission standards (E1/E0), easy handling due to their lightweight nature, and environment-friendly manufacturing. Their smooth finish allows for immediate application without further sanding.Q: How do I ensure proper installation and longevity of Recon Natural Veneers?

A: For best results, apply the veneer sheets on clean, dry, and flat surfaces using suitable adhesives. Maintain indoor moisture levels within the recommended 8%12% range to prevent warping. Routine cleaning and avoiding exposure to excessive moisture or heavy loads will help preserve their appearance and strength.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

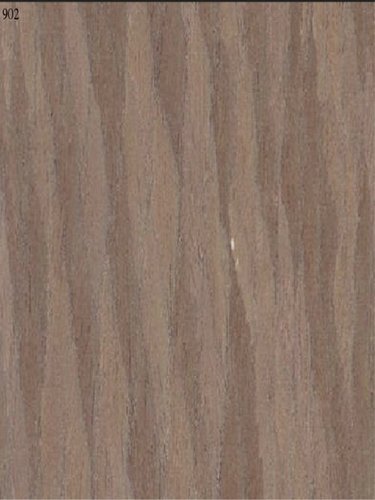

Classic Walnut Veneers

Finish Type : Matte

Grade : AAA

Size : 8ft x 4ft

Usage : Furniture Interior Decoration

Product Type : Other, Veneer

Feature : Durable and aesthetic

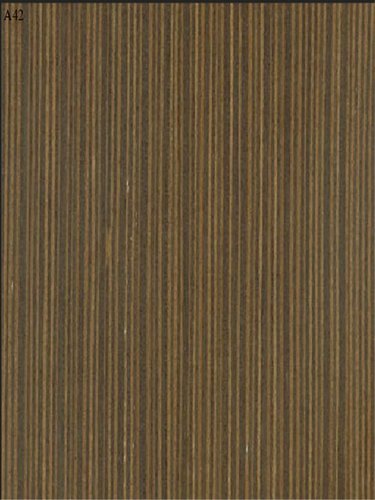

Fineline Wenge Veneers

Finish Type : Matte

Grade : Premium

Size : 2500mm x 1250mm

Usage : Interior decoration furniture making

Product Type : Veneer, Other

Feature : Fine linear grain pattern

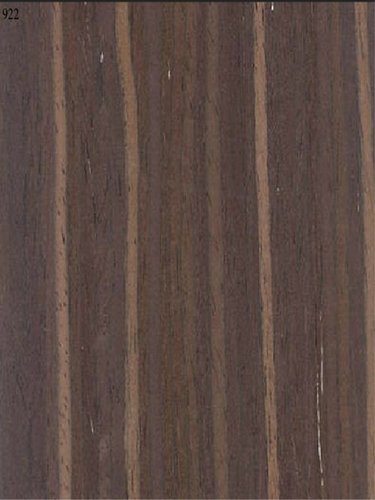

Smoked Wood Veneers

Finish Type : Matte / Semi Gloss

Grade : Premium / A Grade

Size : 8ft x 4ft (2440mm x 1220mm) approx.

Usage : Interior Decoration, Furniture Manufacturing, Wall Paneling

Product Type : Other, Smoked Wood Veneer Sheet

Feature : High Durability, Elegant Appearance, Natural Wood Grain, Smoked Finish

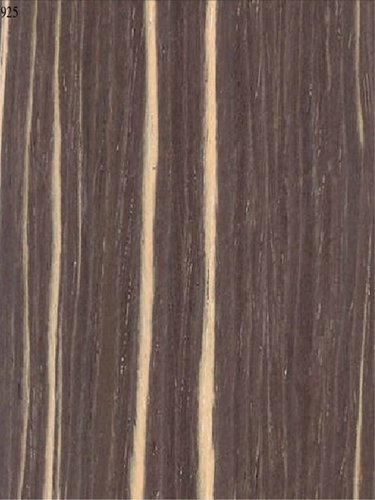

Titan Coffee Veneers

Finish Type : Coffee Finish

Grade : Premium

Size : 8ft x 4ft

Usage : Furniture Interior Design

Product Type : Other, Veneer Sheet

Feature : Durable and Aesthetic

Send Inquiry

Send Inquiry