Teak Veneers

Teak Veneers Specification

- Finish Type

- Unfinished, can be polished or stained

- Tolerance

- 0.1 mm

- Density

- 750 Gram per cubic centimeter(g/cm3)

- Formaldehyde Emission Standards

- E1 grade ( 0.124 mg/m)

- Moisture Content

- 8% 12%

- Wood Type

- Hardwood

- Glue

- Urea Formaldehyde / Phenol Formaldehyde (as required)

- Thickness

- 0.4 mm to 4 mm

- Surface Treatment

- Sanded smooth

- Product Type

- Wood Veneer Sheet

- Usage

- Interior decoration, furniture manufacturing, wall paneling, cabinetry, and doors.

- Grade

- AA, A, AB grades available

- Size

- 8 x 4 feet (standard); custom sizes available upon request.

- Shape

- Rectangular sheet

About Teak Veneers

We are providing to our clients the bulk consignment of quality assured Teak Veneers. Highly durable, these veneers are widely used for designing various wooden items. The veneers, we provide is perfectly finished and polished with the aid of our advanced processing techniques. We follow stringent quality norms in order to maintain the quality and minimize defects during transit of Teak Veneers.

Features:

- Highly flexible

- Weather and chemical resistance

- Perfectly bonded

Superior Quality and Versatility

Our teak veneers are crafted from premium hardwood, offering unmatched stability and elegance. With a choice of finishes and grades, these veneers seamlessly adapt to diverse projects, from intricate cabinetry to expansive wall paneling. Their smooth, sanded surface enables easy customization, ensuring compatibility with a variety of interior styles.

Precision Meets Sustainability

We uphold stringent manufacturing standards, ensuring precision thickness with a tolerance of 0.1 mm and controlled moisture content between 8% and 12%. The use of E1 grade adhesives ensures low formaldehyde emissions, supporting safer and healthier indoor environments for both residential and commercial projects.

Tailored to Your Needs

Our standard 8 x 4 feet sheets cater to most industry requirements, while custom sizing is available for unique projects. Every veneer can be further treated, stained, or polished according to specific design visions, giving you flexibility for creative execution.

FAQs of Teak Veneers:

Q: How are teak veneers typically used in interior design and furniture manufacturing?

A: Teak veneers are commonly applied to surfaces in furniture, cabinetry, wall paneling, and doors. Their fine grain and natural durability make them ideal for interior decorative elements, offering a premium wood appearance with enhanced versatility at a lower cost than solid wood.Q: What process is followed to ensure the quality and safety of these veneers?

A: Our veneers undergo precise sanding for a smooth surface, followed by adherence to E1 formaldehyde emission standards ( 0.124 mg/m). Each sheet is checked for correct thickness, moisture content, and density, and is bonded with either urea or phenol formaldehyde glue as required.Q: When should unfinished teak veneers be polished or stained?

A: Its best to polish or stain the veneers after installation and once all surface preparations are completed. This allows the veneer to properly absorb the finish, achieving optimal color uniformity and long-lasting protection.Q: Where can I request custom sizes or grades for specific projects?

A: Custom size or grade requests can be arranged directly through our export, import, or supply channels in India. Simply provide your project specifications, and our team will accommodate your requirements with precision.Q: What are the primary benefits of using teak veneers over solid teak wood?

A: Teak veneers provide the classic appearance of solid teak while being more cost-effective and resource-efficient. They are easier to handle, allow for greater design flexibility, and offer stable performance with reduced risk of warping, all while maintaining excellent strength and durability.Q: How does the glue type used affect the application and durability of the veneer?

A: The veneer is bonded with either urea formaldehyde (suitable for indoor use) or phenol formaldehyde (for enhanced moisture resistance and durability). The appropriate glue is selected based on end-use, ensuring optimal adhesion and a longer service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

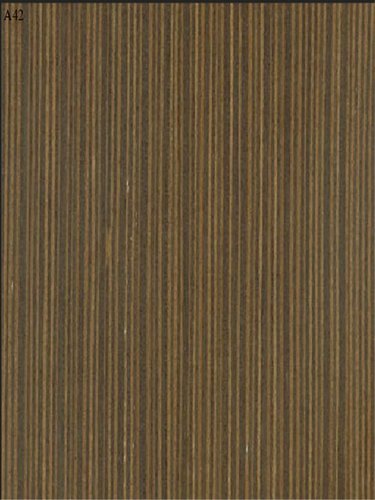

Fineline Wenge Veneers

Usage : Interior decoration furniture making

Grade : Premium

Feature : Fine linear grain pattern

Size : 2500mm x 1250mm

Wood Type : Exotic hardwood

Product Type : Veneer, Other

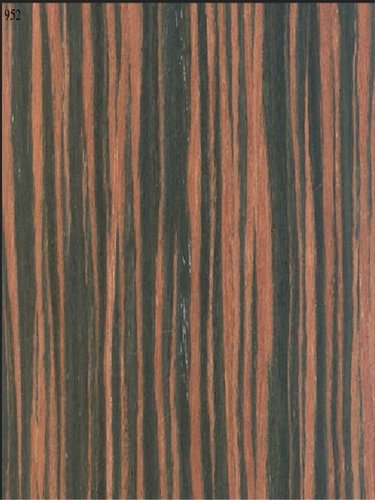

Red Stain Ebony Veneers

Usage : Interior decoration furniture paneling

Grade : Premium

Feature : Decorative surface

Size : 8 ft x 4 ft

Wood Type : Hardwood

Product Type : Veneer, Other

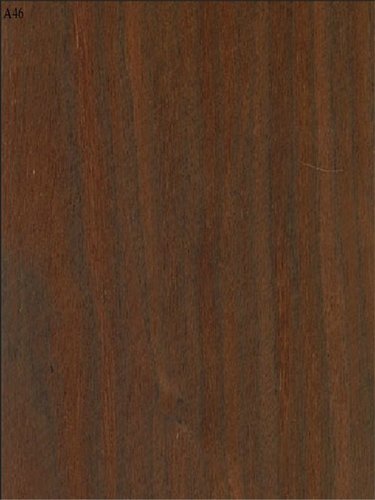

Coco Wood Veneers

Usage : Interior decoration, furniture, wall paneling

Grade : A Grade

Feature : Fine texture, smooth finish, high durability

Size : 8 x 4 ft (Standard)

Wood Type : Hardwood

Product Type : Other, Natural Veneer Sheet

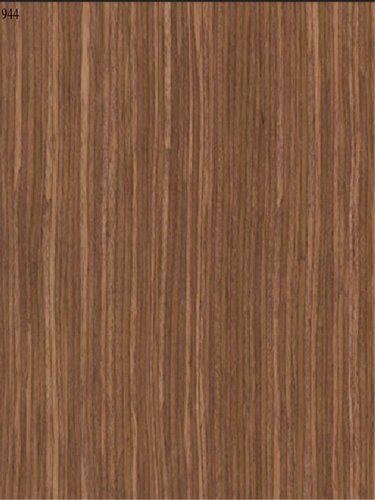

Walnut Quarters Veneers

Usage : Interior decoration furniture cabinetry

Grade : A

Feature : Quarter sliced veneer with natural wood grain pattern

Size : Standard plywood sheet dimensions e.g. 8x4

Wood Type : Walnut

Product Type : Other, Veneer

Send Inquiry

Send Inquiry