Wooden Natural Veneers

Wooden Natural Veneers Specification

- Surface Treatment

- Polished / Unpolished

- Tolerance

- 0.2 mm

- Formaldehyde Emission Standards

- E1 / E0 grade

- Glue

- Urea formaldehyde / Phenol formaldehyde

- Wood Type

- Hardwood

- Load Capacity

- Varies as per substrate and application

- Timber Type

- Usage

- Furniture, paneling, doors, interior design, cabinet making

- Grade

- A / AB / B grade

- Size

- 8 ft x 4 ft (2440 mm x 1220 mm)

- Shape

- Rectangular

About Wooden Natural Veneers

To meet the different requirements of our customers, we are engaged in offering a broad stock of Wooden Natural Veneers. Our clients can avail these veneers from us at market leading prices and also in variable thickness and finishing. These are largely acclaimed across the market for making exclusive furniture, doors, windows and many other items. Further, the entire range of Wooden Natural Veneers offered by us adds elegance and beauty to the finished items.

Features:

- Tolerate severe weather conditions

- Water and termite resistant

- Long life durability

Frequently Asked Questions:

1) What is a natural wood veneer?

Wood veneers in the simplest of terms are thin slices of natural wood generally less than 1/40 inch thick.These veneers are typically pressed onto or laminated to thicker core materials such as plywood, particle board and MDF to create structural panels to be used in place of thicker hardwood lumber.

2) Are wood veneers real wood?

Wood veneers are made by connecting a slight cut of normal wood onto a board of fiberboard or particleboard. It's essential to take note of that facade utilize a piece of genuine wood, not fabricated material made to seem to be wood.

3) Is wood veneer more expensive?

Wood veneer is inherently more expensive than laminate for a number of reasons.This is primarily due to wood veneer being a naturally made product whereas laminate is a man made product. Ultimately, anything that can be mass produced is usually going to be cheaper.

4) Is wood veneer waterproof?

Veneer is susceptible to water damage.Because veneer is glued to the core materials,it is possible for moisture to seep under the veneer and loosen the top layer.This can result in buckling and bubbles. This makes it important to prevent water from sitting on any veneer furniture.

High-Quality Hardwood Veneers

Our wooden natural veneers are meticulously crafted from a selection of premium hardwoods, including Teak, Walnut, Oak, Maple, and other specialty woods. Precision engineering ensures consistent quality, while various grades and finishes provide options for every design need, from high-end cabinetry to sophisticated interior panels.

Versatile Applications for Modern Interiors

These veneers are suitable for a wide variety of uses such as furniture manufacturing, wall paneling, door surfacing, and interior design enhancements. Their rectangular standard size and diverse timber options make them convenient for professional carpenters, architects, and interior decorators alike.

Sustainable and Safe Manufacturing

Adhering to E1 and E0 formaldehyde emission standards, our veneers are both sustainable and safe, prioritizing user health and environmental responsibility. The use of advanced adhesives like urea and phenol formaldehyde ensures long-lasting performance and durability in every application.

FAQs of Wooden Natural Veneers:

Q: How are wooden natural veneers typically used in furniture and interior design?

A: Wooden natural veneers are widely applied to the surfaces of furniture, doors, cabinets, and panels to provide a natural wood appearance, improve aesthetics, and enhance durability without the need for solid wood construction.Q: What types of timber are available for these veneers?

A: You can choose from a variety of hardwoods, including Teak, Walnut, Oak, Maple, and other specialty hardwoods, catering to different design preferences and functional requirements.Q: When should I choose polished or unpolished veneer surfaces?

A: Polished veneers are ideal when a refined, glossy look is desired, while unpolished options are suitable for matte aesthetics or for applications where the final finish will be applied on site.Q: Where are these veneers manufactured and supplied from?

A: These veneers are manufactured, supplied, exported, and imported by reputable companies based in India, ensuring international quality standards and reliable delivery.Q: What is the process for applying wooden veneers to furniture or panels?

A: Application typically involves cutting the veneer to size, applying a suitable adhesive (such as urea or phenol formaldehyde glue), pressing the veneer onto the substrate, and finishing with sanding or polishing as needed.Q: How does the grade and formaldehyde emission standard affect veneer selection?

A: Grades (A, AB, B) indicate the visual and structural quality of the veneers, while E1/E0 emission standards guarantee low formaldehyde release, contributing to better indoor air quality and safe usage in sensitive environments.Q: What are the main benefits of using natural hardwood veneers?

A: Natural veneers combine the beauty of real wood with cost-effective, sustainable resource use. They offer flexibility in design, ease of application, and ensure lower formaldehyde emissions for healthier living spaces.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Natural Veneers Category

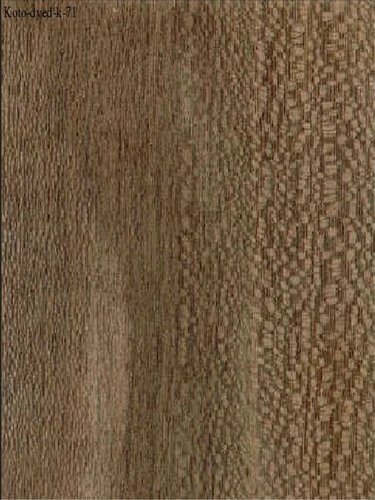

Koto-Dyed-K-71 Veneers

Product Type : Veneers

Wood Type : Koto

Size : Provide size dimensions

Usage : Provide usage information

Grade : K71

Feature : Provide feature description

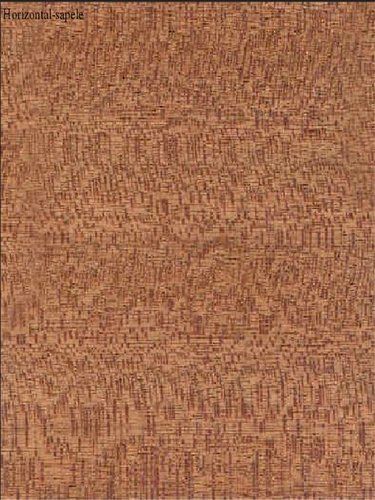

Horizontal Sapele Veneers

Product Type : Other, Horizontal Veneers

Wood Type : Sapele

Size : Standard

Usage : Furniture and interior decoration

Grade : A

Feature : High durability

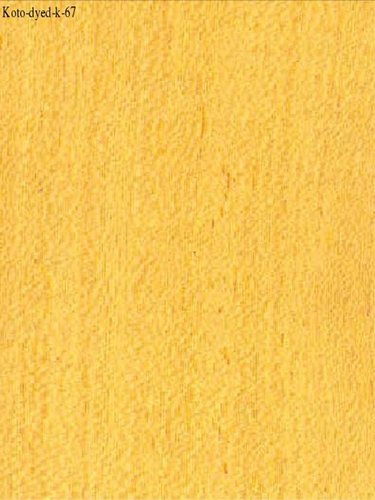

Koto-Dyed-K-67 Veneers

Product Type : Veneer, Other

Wood Type : Koto

Size : Not Available

Usage : Furniture Interiors

Grade : Premium

Feature : Dyed Veneer

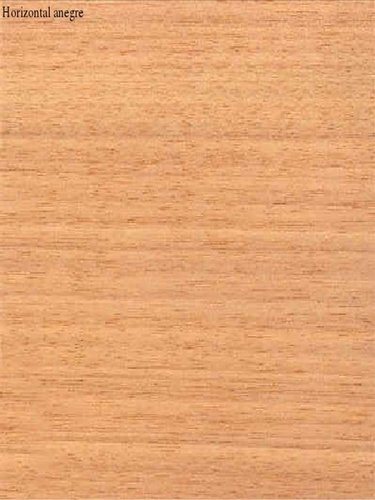

Horizontal Anegre Veneers

Product Type : Other, Veneer

Wood Type : Anegre

Size : Standard

Usage : Furniture interiors and surface finishes

Grade : Premium

Feature : Horizontal grain pattern

Send Inquiry

Send Inquiry