Plywood Veneers

Plywood Veneers Specification

- Core Material

- Poplar, Eucalyptus, Hardwood

- Formaldehyde Emission Standards

- E0, E1, E2

- Finish Type

- Smooth Polished

- Tolerance

- 0.2mm

- Glue

- Melamine or Phenol Formaldehyde

- Thickness

- 3mm to 25mm

- Load Capacity

- High Load Bearing Capacity

- Product Type

- Plywood Veneers

- Timber Type

- Hardwood

- Usage

- Furniture, Doors, Cabinets, Paneling, Architectural applications

- Grade

- First Grade, Premium, Commercial

- Size

- 8ft x 4ft, 6ft x 4ft, Custom Sizes Available

- Feature

- Fine finish, Durable, Termite Resistance, Moisture Resistant

- Shape

- Rectangular

About Plywood Veneers

Sparkling smoothness and unmatched quality makes the stock of Plywood Veneers demanded across the market. All these strong wooden veneers get processed and smoothened with the help of advanced wood shaping & cutting tools. We specifically deliver these slabs for designing purpose of several wood items, furniture, windows and doors. Our gamut of Plywood Veneers is supplied to the clients specified location within promised time frames and at market leading prices.

Features:

- Perfect thickness

- Perfectly polished

- Crack resistant

Versatile Applications

Our plywood veneers are highly suitable for a wide variety of uses including bespoke furniture pieces, architectural paneling, premium doors, and cabinetry. The available thickness range (3mm to 25mm) and the option for custom sizes enable adaptability in both residential and commercial projects. Their robust core and high load-bearing capacity make them a preferred choice among designers and architects.

Engineered for Enduring Performance

Manufactured using melamine or phenol formaldehyde glues, our veneers promise remarkable durability and resistance to both moisture and termites. With smooth, polished surfaces and a tolerance of 0.2mm, these products deliver aesthetic finesse while maintaining structural integrity. Adherence to formaldehyde emission standards ensures health and environmental safety for every project.

FAQs of Plywood Veneers:

Q: How can plywood veneers be utilized in architectural applications?

A: Plywood veneers are widely used in architectural projects for paneling, partition walls, and decorative surfacing thanks to their durability, smooth finish, and ability to be customized in size and thickness. Their high load-bearing capacity makes them suitable for both structural and aesthetic purposes.Q: What are the benefits of choosing hardwood plywood veneers for furniture and cabinetry?

A: Hardwood plywood veneers offer superior strength, fine finish, and enhanced durability. They are termite and moisture resistant, making them long-lasting solutions for furniture and cabinets that demand both resilience and visual appeal.Q: Where are your plywood veneers manufactured and can they be exported globally?

A: Our plywood veneers are manufactured in India, adhering to international standards. As experienced exporters, importers, and suppliers, we cater to both domestic and international markets, ensuring timely delivery and product quality worldwide.Q: What is the process behind ensuring the fine finish and durability of your plywood veneers?

A: The veneers are crafted using select timber types, bonded with melamine or phenol formaldehyde glue, and processed under strict quality controls. The smooth polished finish and precise thickness tolerances are achieved through advanced machinery and inspection protocols.Q: When should I consider custom sizes for plywood veneers?

A: Custom sizes are ideal when your project requires non-standard dimensions to accommodate unique designs or architectural features. Our manufacturing capabilities allow us to produce veneers tailored to your specifications, ensuring a perfect fit every time.Q: How does your plywood meet formaldehyde emission standards?

A: Our products are tested to comply with E0, E1, and E2 formaldehyde emission standards, ensuring low emissions for safer indoor air quality. This makes our plywood veneers suitable for environments with stringent health and safety requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

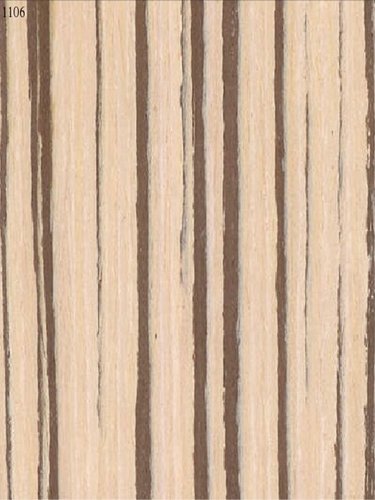

White Ebony Veneers

Grade : Premium / AA Grade

Product Type : Veneer, Other

Size : 8x4 Feet

Usage : Furniture Interior Panelling

Core Material : Natural Hardwood Base

Surface Treatment : Polished

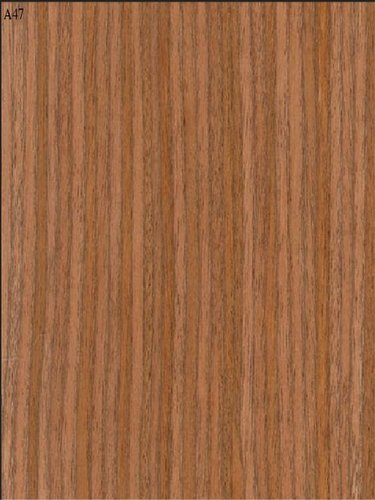

Irish Rose Wood Veneers

Grade : A Grade

Product Type : Other, Natural Veneer Sheet

Size : 8 x 4 Feet (Standard)

Usage : Furniture, Interior Decoration, Paneling, Cabinet Making, Architectural Applications

Core Material : Not Applicable (Face Veneer Product)

Surface Treatment : Sanded, Prepressed

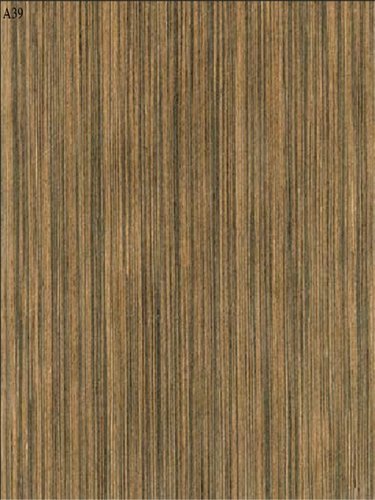

Dark Wenge Veneers

Grade : Premium

Product Type : Other, Veneer

Size : 8ft x 4ft

Usage : Furniture Wall Paneling Interior Decoration

Core Material : Plywood

Surface Treatment : Polished

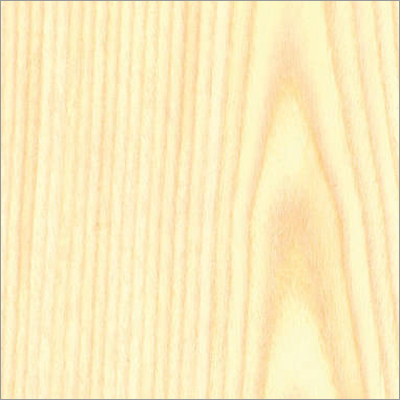

Engineered Recon Veneers

Grade : A Grade / Premium

Product Type : Other, Engineered Recon Veneer

Size : 8 x 4 Feet (Standard)

Usage : Interior Decoration, Furniture, Paneling, Door and Cabinet Surfacing

Core Material : Poplar, Eucalyptus, or Mixed Hardwood Core

Surface Treatment : Calibrated and Sanded

Send Inquiry

Send Inquiry