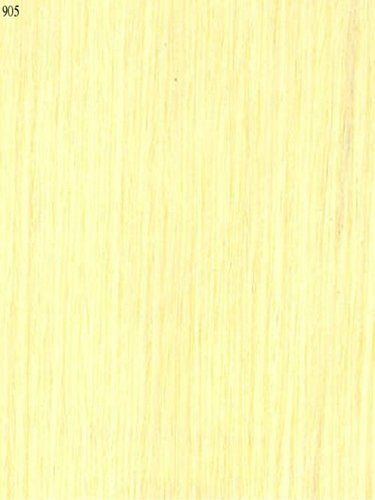

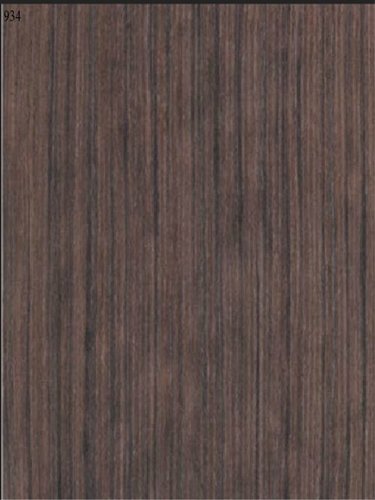

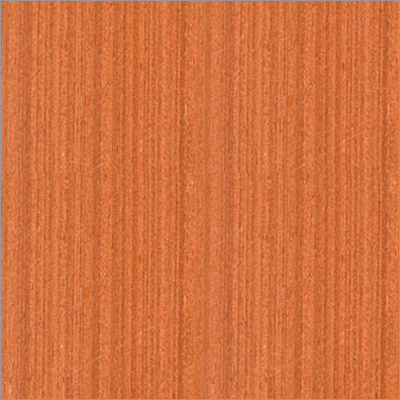

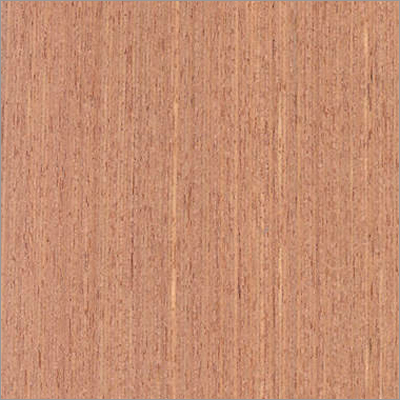

Reconstituted Wood Veneers

Reconstituted Wood Veneers Specification

- Thickness

- 0.5 mm to 2 mm

- Wood Type

- Artificial Wood Veneer

- Glue

- Urea Formaldehyde / Melamine Formaldehyde

- Moisture Content

- 8% to 10%

- Formaldehyde Emission Standards

- E1 / E0

- Product Type

- Reconstituted Wood Veneer Sheet

- Timber Type

- Engineered Wood

- Usage

- Interior Decoration, Furniture Making, Paneling, Door Skins

- Grade

- A Grade

- Size

- 8 ft x 4 ft

- Shape

- Rectangular

About Reconstituted Wood Veneers

Leveraging on the association with the entire market, we are indulged in offering to our customers a wide variety of Reconstituted Wood Veneers. The provided wood is suitable for designing several wood items like furniture and other accessories. These veneers are finely processed by cutting, finishing and polishing the surface to provide protection from water and termite. Offered Reconstituted Wood Veneers are available in different rich colors, fine texture, sizes and thicknesses to cater clients specific needs.

Features:

- Immune to bio-degradation

- High strength

- Resistive against fungus and rots

Versatile Applications

Our reconstituted wood veneers are engineered for versatility, making them an excellent choice for a range of interior applications. From creating stylish furniture and contemporary paneling to beautifying door skins, these veneers provide a uniform and attractive finish, elevating any space. Their adaptability ensures that designers and manufacturers have consistent materials for both commercial and residential projects.

Sustainable and Safe Choice

Made from high-quality engineered wood, these artificial veneers represent a sustainable approach, reducing pressure on natural forests. Our products adhere to strict E1 and E0 formaldehyde emission standards, ensuring healthier indoor environments. With advanced bonding resins and controlled moisture content, our veneers promise longevity and environmental responsibility, making them a preferred option for eco-conscious projects.

FAQs of Reconstituted Wood Veneers:

Q: How are reconstituted wood veneers manufactured?

A: Reconstituted wood veneers are produced by slicing, dyeing, and laminating engineered wood layers. These layers are bonded using urea formaldehyde or melamine formaldehyde adhesives, then pressed and cut to uniform sizes, ensuring consistent color, pattern, and thickness ranging from 0.5 mm to 2 mm.Q: What are the typical uses of reconstituted wood veneers?

A: These veneers are commonly utilized in interior decoration, furniture manufacturing, wall paneling, and door skin applications. Their precise dimensions and consistency make them a popular choice for designers seeking reliable, aesthetic surfaces for both commercial and residential settings.Q: When should I consider using reconstituted wood veneers over natural veneers?

A: Reconstituted wood veneers are ideal when you need uniformity in color and grain, greater quantity, or a sustainable alternative. They are also preferred when meeting strict formaldehyde emission regulations is necessary, especially for indoor projects and public spaces.Q: Where can I source high-quality reconstituted wood veneers in India?

A: As a leading exporter, importer, manufacturer, and supplier based in India, we provide high-grade reconstituted wood veneers nationwide. Our extensive distribution network ensures timely supply to businesses, architects, and furniture makers across the country.Q: What is the benefit of choosing A-Grade artificial wood veneers?

A: A-Grade artificial wood veneers are processed to deliver superior durability, uniformity, and appearance. They offer enhanced moisture resistance (8%10%), reduced defects, and compliance with E1/E0 standards for lower formaldehyde emissions, safeguarding indoor air quality.Q: What formaldehyde emission standards do your veneers meet?

A: Our reconstituted wood veneers comply with international E1 and E0 formaldehyde emission standards, ensuring minimal chemical release and safer environments for your interiors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

White Ash Quarter Veneers

Product Type : Other, Veneer

Size : 4x8 feet

Usage : Furniture paneling and decorative applications

Feature : Quarter cut veneer with uniform grain pattern

Grade : A

Wood Type : White Ash

Brazilian Rosewood Veneers

Product Type : Other, Natural Wood Veneer Sheet

Size : 8 ft x 4 ft, customized sizes available

Usage : Furniture, interior decoration, musical instruments

Feature : High durability, rich color, elegant grain

Grade : A Grade

Wood Type : Hardwood

Plywood Veneers

Product Type : Other, Plywood Veneers

Size : 8ft x 4ft, 6ft x 4ft, Custom Sizes Available

Usage : Furniture, Doors, Cabinets, Paneling, Architectural applications

Feature : Fine finish, Durable, Termite Resistance, Moisture Resistant

Grade : First Grade, Premium, Commercial

Guitar Wood Veneers

Product Type : Other, Wood Veneer Sheet

Size : Custom/Standard Sizes Available

Usage : Guitar Manufacturing

Feature : High Durability, Smooth Surface, Easy To Work With

Grade : A

Wood Type : Maple, Rosewood, Mahogany, Walnut, etc.

Send Inquiry

Send Inquiry