Dyed Veneer

Dyed Veneer Specification

- Core Material

- Oak Wooden

- Moisture Content

- Greater than 5%-Less than 15%

- Thickness

- 4-19 Micrometers (um)

- Product Type

- Dyed Veneer

- Usage

- Furniture

- Size

- 8x4 Feet

- Shape

- Rectangle

About Dyed Veneer

Over the years, we have been actively engaged in manufacturing and exporting an exclusive array of Dyed Veneer. All these wood logs are superior in finish that has been obtained by appropriately cut and polished the natural wood. We have a wide array of veneers that is available to our customers in several shades, sizes and thickness standards. Further, we deliver the assortment of Dyed Veneer in custom specifications and also at pocket friendly prices of our customers.

Features:

- Resistive against fungus

- Strongly built

- Moisture proof

Precision-Crafted Dyed Veneer for Furniture

Each veneer sheet features a refined oak core and is dyed to achieve lasting color without sacrificing natural wood appeal. Enhanced with optimal moisture levels, our veneers ensure durability and easy handling during furniture production, making them a reliable choice for both artisans and manufacturers.

Versatile Applications and Easy Integration

Designed primarily for crafting furniture, our 8x4 feet dyed veneer fits seamlessly into a variety of projects. Whether you are creating cabinets, tables, or decorative panels, the thin yet robust structure allows for smooth application and superior finishing, elevating both aesthetics and performance.

FAQs of Dyed Veneer:

Q: How is the dyed veneer manufactured and dyed?

A: The dyed veneer is produced by slicing high-quality oak wood into thin sheets, followed by a dyeing process where the veneers absorb vibrant colors. This ensures uniform coloration throughout each sheet while retaining the natural grain and strength of the oak core.Q: What makes the specified moisture content important for this veneer?

A: Maintaining a moisture content between 5% and 15% prevents warping and cracking. This range is optimal for preserving the veneers structural integrity during processing and ensures the finished furniture remains stable in various climates.Q: When should I use dyed veneer over other surface materials for furniture?

A: Dyed veneer is recommended when you desire the natural elegance of wood with added color options. It is particularly suited for high-end furniture, decorative panels, and spaces where appearance and longevity are paramount.Q: Where can this dyed veneer be applied within furniture design?

A: This veneer can be applied to cabinet doors, tabletops, wall panels, and other flat surfaces in furniture design. Its standard 8x4 feet size accommodates most commercial and residential furniture projects.Q: What benefits does using an oak wooden core provide?

A: An oak wooden core enhances the veneers durability and workability, offering a strong, stable substrate that can be cut, glued, and finished easily, while the dyed layer maintains a sophisticated, customizable appearance.Q: How is the veneer typically processed and applied during furniture making?

A: The veneer sheets are glued onto prepared substrates using adhesive or pressing methods. They can be trimmed, sanded, and finished as desired, allowing flexibility in achieving the desired style and smoothness.Q: What advantages are offered by sourcing from an Indian exporter and manufacturer?

A: Purchasing from an Indian exporter or manufacturer ensures access to competitively priced, quality-assured dyed veneers produced in accordance with global standards, along with reliable supply chains for both domestic and international projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Natural Veneers Category

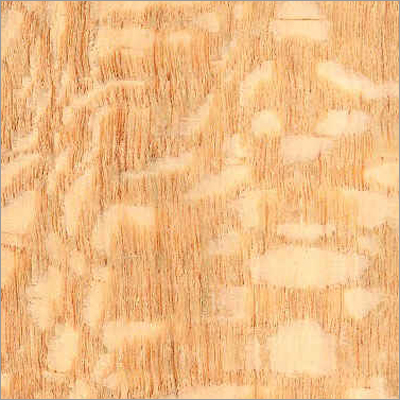

Figuara-Crowa Veneers

Grade : Premium

Usage : Furniture Decor

Product Type : Veneers

Wood Type : Teak

Feature : Durable

Size : 8x4 ft

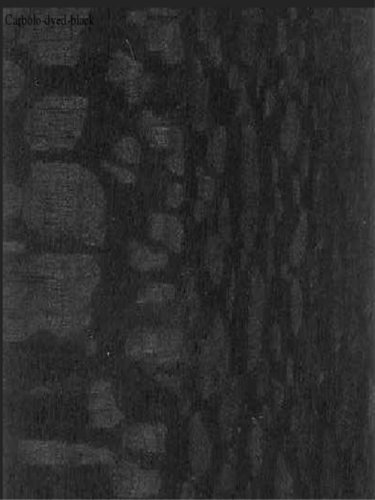

Carbolo-Dyed-Black Veneers

Grade : Premium

Usage : Furniture Interior Design Decorative Panels

Product Type : Other, Veneer

Wood Type : Engineered Wood

Feature : Dyed Black Enhanced Visual Pattern

Size : 1220mm x 2440mm

Horizontal Weuge Veneers

Grade : Premium

Usage : Furniture interior design

Product Type : Other, Horizontal Weuge Veneers

Wood Type : Natural veneer

Feature : Horizontal grain pattern

Size : Standard sheet size

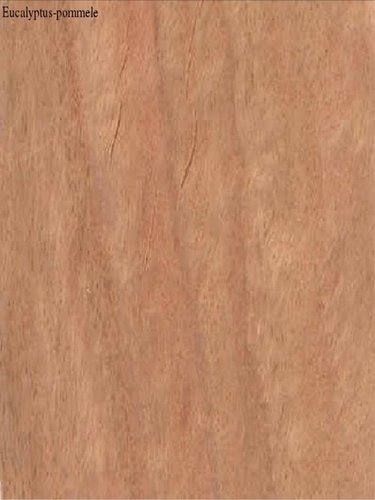

Eucalyptus-Pommele Veneers

Grade : A

Usage : Furnishing paneling cabinetry

Product Type : Other, Wood Veneer

Wood Type : Eucalyptus

Feature : Natural Pommele grain pattern

Size : Standard sizes available

Send Inquiry

Send Inquiry