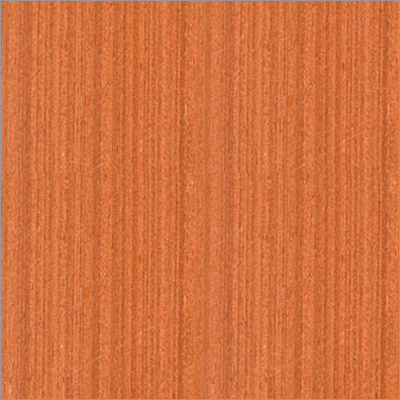

Koto Dyed White Veneers

Koto Dyed White Veneers Specification

- Thickness

- 0.6mm

- Formaldehyde Emission Standards

- E1 Standard

- Finish Type

- White Finish

- Surface Treatment

- Smooth

- Moisture Content

- Low

- Tolerance

- 0.1mm

- Density

- Gram per cubic centimeter(g/cm3)

- Load Capacity

- High

- Wood Type

- Hardwood

- Core Material

- Koto Wood

- Glue

- Eco-Friendly Glue

- Product Type

- Veneer

- Timber Type

- African Koto

- Usage

- Furniture and Interior

- Grade

- A Grade

- Size

- 8ft x 4ft

- Feature

- Dyed Veneers

- Shape

- Flat Sheet

About Koto Dyed White Veneers

Ephemeral Elegance Meets Industrial Strength

Koto Dyed White Veneers are highly prized in plant applications for their precision, stability, and smooth surface. Crafted for robust machine handling, their high load capacity, low moisture content, and 0.1mm tolerance ensure optimal performance in furniture fabrication and interior design. These veneers feature a dyed white finish applied via premium machinery, delivering consistency and a remarkable surface suited to projects demanding both visual finesse and technical excellence.

Swift Export, Accredited Quality, and Global Markets

With our proposal amount tailored for international clientele and stock ready for quick dispatch, Koto Dyed White Veneers are available ex-works from Indias leading FOB ports. We maintain rapid lead times and focus on seamless logistics. Our main export markets include Europe, the Middle East, and Southeast Asia, backed by relevant certifications and adherence to E1 standards. Buyers are guaranteed a swift, reliable supply chain for every order.

FAQs of Koto Dyed White Veneers:

Q: How are Koto Dyed White Veneers manufactured to achieve a flawless white finish?

A: These veneers are processed using advanced machinery and dyed techniques, ensuring an even, smooth white finish paired with high durability and precision.Q: What is the main benefit of using Koto Dyed White Veneers in furniture making?

A: Their high load capacity, low moisture, and crack resistance make them ideal for both structural integrity and exquisite aesthetics in furniture and interiors.Q: When is stock available for dispatch after placing a proposal amount?

A: Our veneers are generally stock ready, facilitating quick dispatch soon after order confirmation and completion of proposal formalities.Q: Where are these veneers exported from and what are the main global markets?

A: Exports are facilitated from key Indian ports, serving major markets including Europe, the Middle East, and Southeast Asia.Q: What formaldehyde emission standard do these veneers conform to?

A: They adhere strictly to the E1 standard, ensuring minimal formaldehyde emissions for healthier environments.Q: How precise is the thickness and tolerance specification of these veneers?

A: Each sheet offers a consistent thickness of 0.6mm with a tight tolerance of 0.1mm, meeting demanding project requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Recon Veneers Category

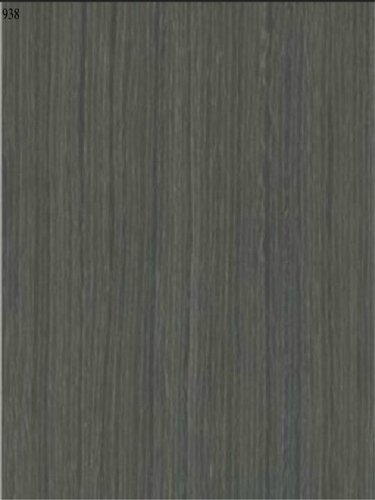

Ash Dyed Metal Grey Veneers

Size : 8ft x 4ft

Feature : Dyed Wood Veneer

Usage : Furniture Interior Design

Grade : Premium

Finish Type : Metal Grey

Product Type : Other, Veneer

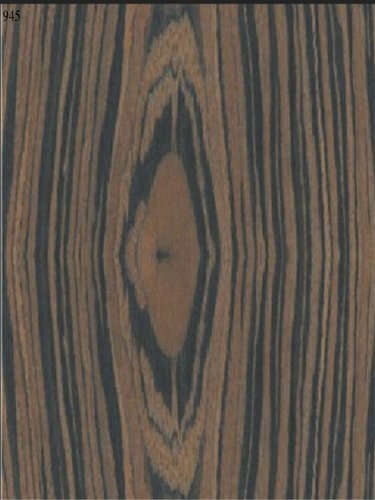

Ebony Crown Veneers

Size : 8x4 ft

Feature : Decorative

Usage : Furniture interiors and cabinetry

Grade : Premium

Finish Type : Polished

Product Type : Other, Veneer

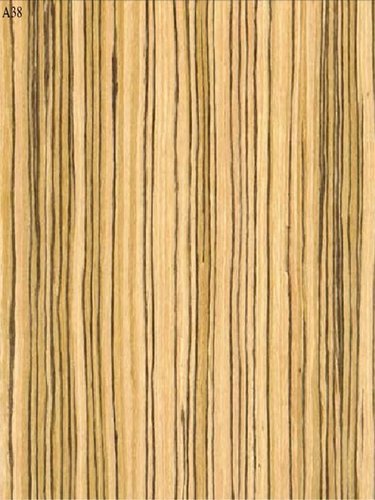

Wild Wood Veneers

Size : 1200mm x 2400mm

Feature : Natural Wood Veneer

Usage : Furniture decoration wall panels

Grade : Premium

Finish Type : Polished

Product Type : Veneers

Plywood Veneers

Size : 8ft x 4ft, 6ft x 4ft, Custom Sizes Available

Feature : Fine finish, Durable, Termite Resistance, Moisture Resistant

Usage : Furniture, Doors, Cabinets, Paneling, Architectural applications

Grade : First Grade, Premium, Commercial

Finish Type : Smooth Polished

Product Type : Other, Plywood Veneers

Send Inquiry

Send Inquiry